Climate Insider Brief:

- A team of researchers at the University of Toronto has developed a new method to recycle steel using an oxysulfide electrolyte for electrorefining, which can remove copper and other impurities from molten steel, producing high-grade products.

- The new method can expand the secondary steel market into industries that currently rely on higher-grade steel products, such as the automotive and transport sectors.

- The team is working with Tenova Goodfellow Inc. to further develop the electro-refining process, aiming to remove other contaminants like tin from steel.

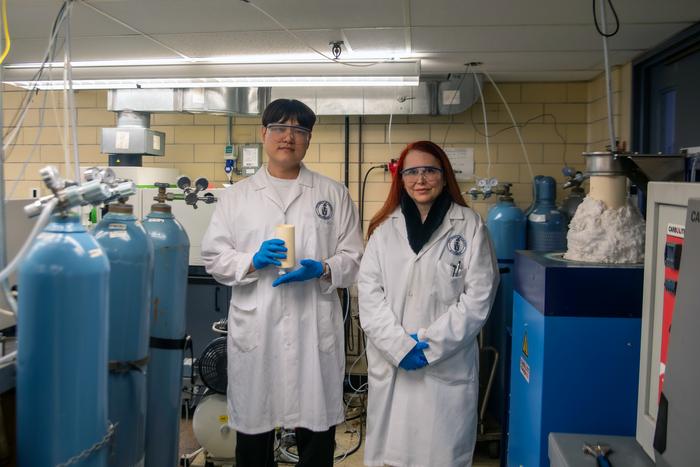

A team of researchers at the University of Toronto has developed a groundbreaking method to recycle steel in a way that could significantly reduce the carbon footprint of the manufacturing industry. The innovative approach, outlined in a new paper, introduces an oxysulfide electrolyte for electrorefining, which can remove copper and other impurities from molten steel, producing high-grade products.

Currently, only 25% of steel is produced from recycled material, and the demand for greener steel is expected to grow as governments aim to achieve net-zero emission goals. Traditional steel recycling methods use electric arc furnaces, which are limited in their ability to remove copper from scrap metal, resulting in lower-quality steel products. The new method, on the other hand, can remove copper from iron to below 0.1%, allowing for the production of higher-grade products.

The team designed an electrochemical cell that can withstand temperatures up to 1600 degrees Celsius, using a novel oxysulfide electrolyte derived from slag waste. The process involves applying electricity between two electrodes, with the contaminated iron serving as the anode, and forcing the copper to react with the electrolyte. This produces liquid iron and sulfur as by-products.

The implications of this breakthrough are significant. The method can expand the secondary steel market into industries that currently rely on higher-grade steel products, such as galvanized cold rolled coil used in the automotive sector or steel sheets for deep drawing used in the transport sector. With this technology, the steelmaking industry could produce more high-grade steel globally while reducing its carbon footprint.

The team is already working with Tenova Goodfellow Inc. to develop the electro-refining process further, aiming to remove other contaminants like tin from steel. With iron and steel being the most widely used metals in industry, this innovative approach has great potential to offer a practical and easily implementable solution for a greener future.

SOURCE: EurekAlert

Featured Image: Credit: University of Toronto