Insider Brief

- A consortium including CB&I, Shell, GenH2, and the University of Houston has completed a novel, affordable large-scale liquid hydrogen (LH2) storage tank concept at NASA’s Marshall Space Flight Center.

- The design eliminates the need for traditional vacuum insulation, enabling cost-effective storage of up to 100,000 cubic meters of LH2 for international trade applications, with testing supported by the U.S. Department of Energy.

- The tank’s demonstration will aid material testing and insulation innovation over a five-year period, positioning U.S. partners as leaders in scalable hydrogen infrastructure for a global energy transition.

PRESS RELEASE – CB&I and a consortium including Shell International Exploration and Production, Inc. (Shell), a subsidiary of Shell plc, GenH2 and the University of Houston announced the completion of a first-of-its-kind, affordable, large-scale liquid hydrogen (LH2) storage tank concept at NASA’s Marshall Space Flight Center (MSFC) in Huntsville, Alabama, that will enable international import and export applications.

“Our collaboration with this world-class project team will help provide a path to low-cost, large-scale liquid hydrogen storage,” said Mark Butts, President & CEO of CB&I. “We are proud to leverage our six decades of experience with cryogenic insulation and storage to advance innovative solutions for the energy transition market.”

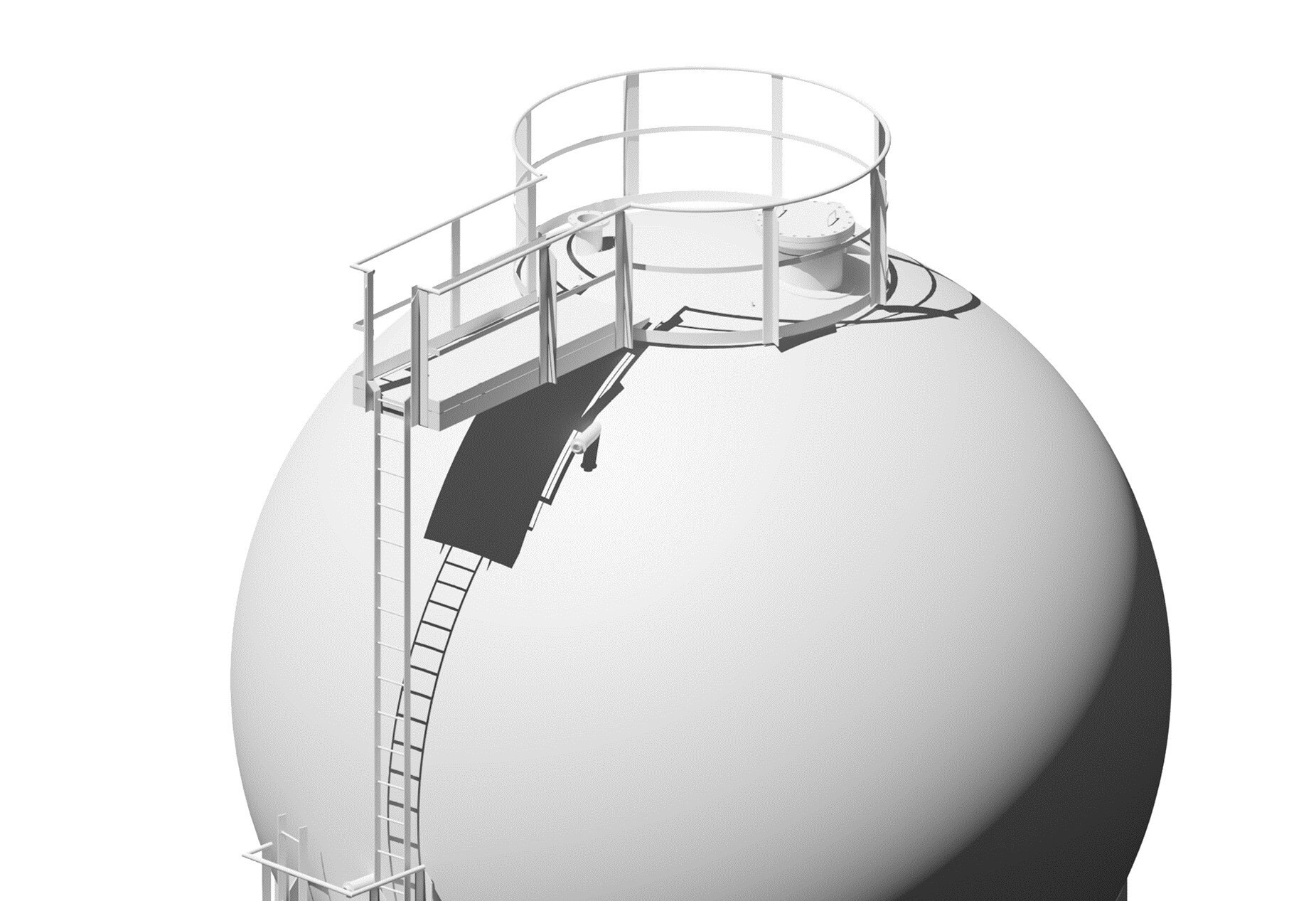

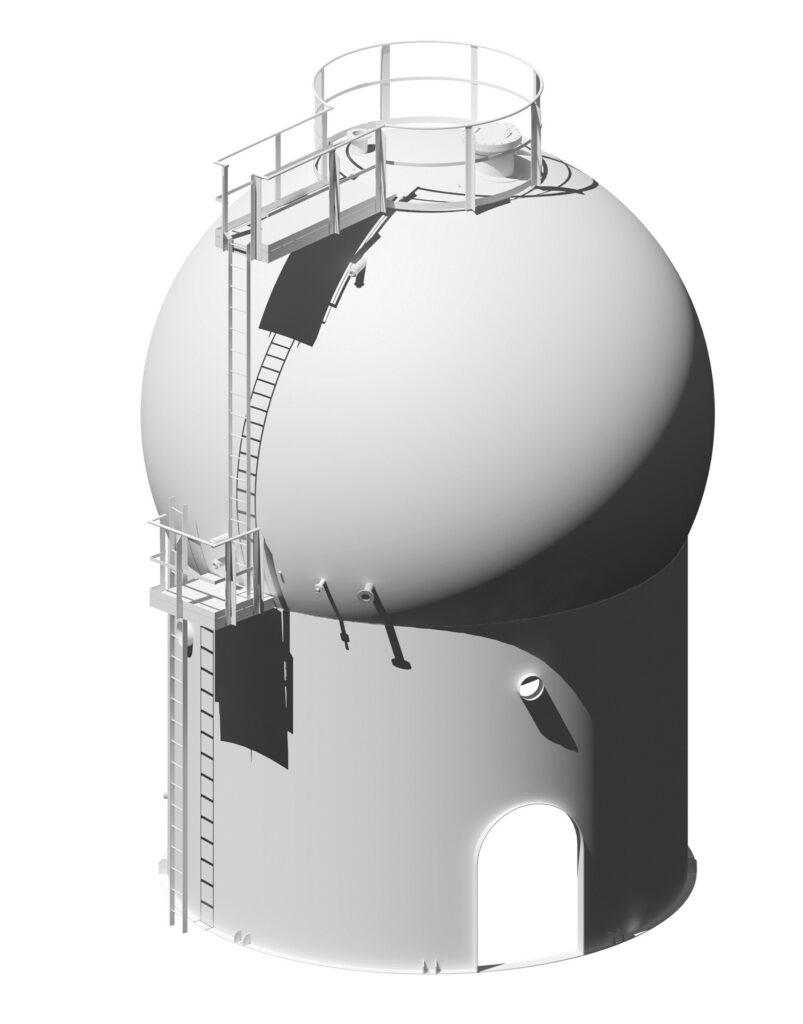

The project, which began in 2021 and is supported by the US Department of Energy (DOE), developed a novel non-vacuum tank design concept for large-scale (up to 100,000 cubic meters) storage of LH2 that is anticipated to provide a substantial cost advantage over conventional vacuum insulated tanks. This concept is being demonstrated through the construction, startup and testing of a small-scale LH2 demonstration tank at NASA MSFC.

“At Shell, we believe in the power of collaboration to advance technology and scale up innovative solutions,” said Theo Bodewes, General Manager, Hydrogen Technology. “With the invaluable support from the DOE, this project demonstrates how experts from industry, academia, and government can solve complex technology challenges. This novel liquid hydrogen technology promises to be more competitive, reducing costs and accelerating large-scale storage commercialization.”

The demonstration tank will significantly increase the MSFC hydrogen test facility’s LH2 storage capacity and be used to characterize the behavior of materials under cryogenic conditions, mimicking normal fill and empty cycles and testing non-vacuum insulation materials. In addition to an estimated six-month test period included in the project scope, a Space Act Agreement among the partner organizations provides for MSFC’s use of the tank over a five-year period, during which CB&I and Shell will continue to test new insulation technologies under non-vacuum conditions.

“We take pride in participating in this industry collaboration to advance commercial liquid hydrogen storage applications,” said James Fesmire, GenH2 Chief Architect. “This initiative has allowed us to develop testing capabilities for thermal insulation systems and produce essential data for unlocking the global potential of liquid hydrogen.”

“This project is an example of a novel design brought to fruition by a partnership of academia, government agencies, and the energy companies,” said Dr. Ramanan Krishnamoorti, Vice President of Energy and Innovation at the University of Houston. “The ability to store liquid hydrogen at scale using a non-vacuum design is a pivotal advancement and opens the door to a more flexible, affordable global hydrogen trade infrastructure. Innovative solutions such as this will be key to advancing our energy economy.”

“This first-of-its-kind concept is a great example of unleashing American energy innovation – a key priority for the Department of Energy. Through collaborative expertise from industry, academic, and government agencies, this work can contribute to America’s leadership in growing global markets for hydrogen and hydrogen-based fuels and offer greater opportunities for American energy operators to store, deploy, and export liquid hydrogen,” said Dr. Sunita Satyapal, director of DOE’s Hydrogen and Fuel Cell Technologies Office.

CB&I built the first LH2 sphere for NASA and NASA contractors in the 1960s, with a capacity of 170 cubic meters, and has expanded that threshold over the last sixty years by almost 30-fold to 5,000 cubic meters with a tank completed in 2022 at Kennedy Space Center for the Artemis program. CB&I has completed over 130 LH2 storage vessels since the 1960s.

The company and NASA have had a partnership of more than 60 years, with CB&I contributing to many NASA projects, including several supporting the Apollo and Gemini space missions.