- MacroCycle Technologies wins the World Cup of Startups at San Francisco Climate Week.

- The technology recycles plastic in a low-cost, low-energy process.

- MacroCycle will compete with other regional winners at the grand finale in October for US$1 million in funding.

Stwart Peña Feliz was shocked and surprised to learn that his climate tech company, plastic recycling MacroCycle Technologies co-founded with Jan-Georg Rosenboom, won the World Cup of startups at San Francisco Climate Week in April.

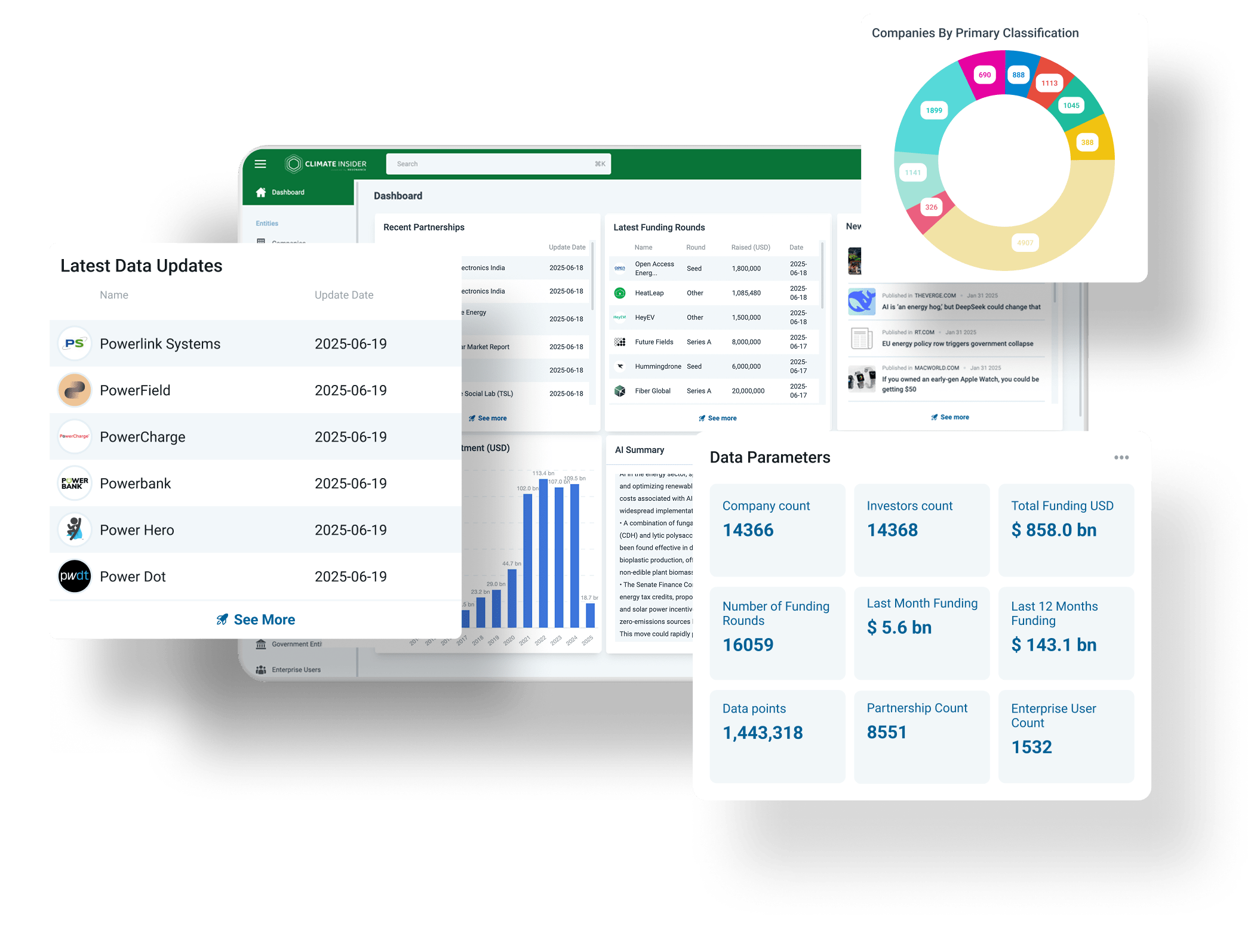

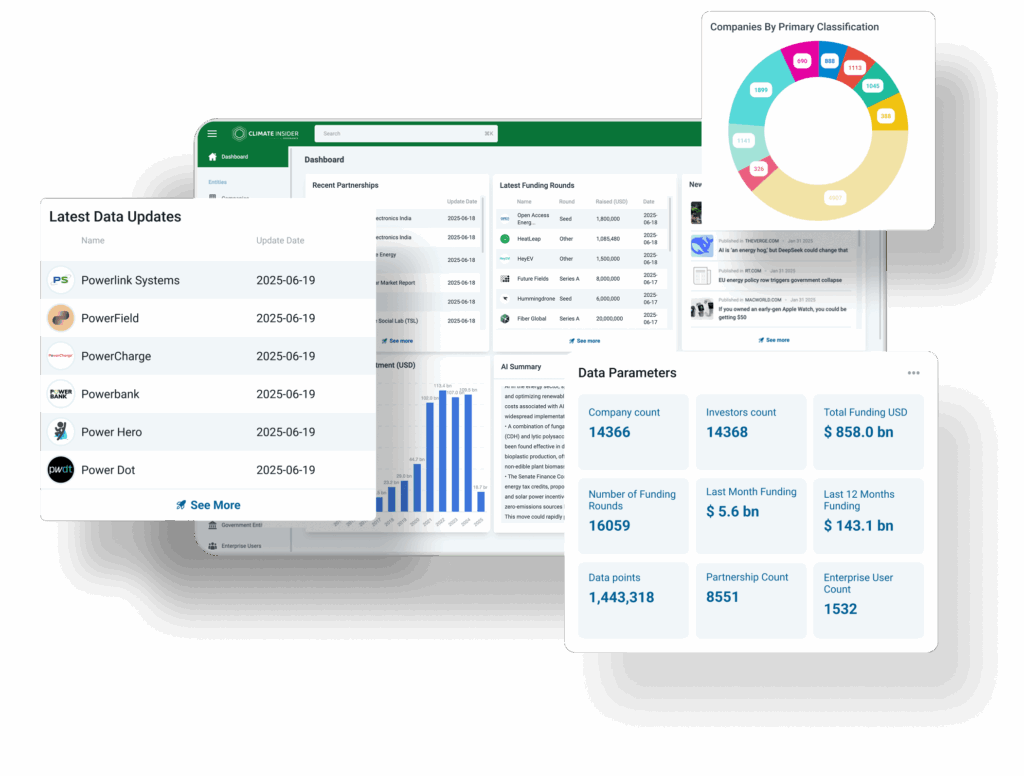

The company beat out nine other competitors, in a competition sponsored by Climate Insider. “I was shocked and surprised that we won,” Peña Feliz told Climate Insider.

MacroCycle applies polymer science to decarbonize plastics recycling, Peña Feliz said. “This isn’t carbon capture – but we can eliminate the carbon footprint in the plastics production cycle.”

The startup was founded in Cambridge, where the two co-founders met while pursuing studies at the Massachusetts Institute of Technology.

The pair turned their attention to the enormous amount of plastic pollution.

“Today, over 85% of all plastics and textiles produced wind up in our oceans or is incinerated,” Peña Feliz said.

MacroCycle’s technology is a break with traditional plastics recycling, usually done by a process called mechanical recycling, Peña Feliz said. “This recycling cannot remove colours or contaminants. It can’t take the green out of green bottles – it can turn a bottle into a T-shirt, but not the other way around.”

Another type of recycling is chemical recycling , which breaks the plastic down to a molecular level to its elemental building blocks.

“It provides building blocks back to its petrochemical base to be re-made into traditional plastic,” Peña Feliz said. “It’s very energy-intensive and costly.”

Reimagining plastics recycling

MacroCycle Technologies bypasses petrochemicals entirely.

“Macrocycles are intermediates of cyclic molecules, and which allow us to create a long molecular chain of polymer through our chemistry. Chemical recyclers are trying to break the plastic back to building blocks,” Peña Feliz said.

Instead, MacroCycle is building bonds, instead of breaking bonds.

“We take the polymer chains, and tie them to create macrocycles,” he said. “We can open them up, in a process called ring opening polymerization, and create longer chains.”

These longer chains are higher quality and don’t break down. “It’s a significantly more energy efficient pathway, at low-cost, and there’s no green premium required for adoption,” Peña Feliz said.

“We recycle bottle to bottle or textile to textile, with PET bottles or polyester textile applications, so a packaging company or a milling or fashion company can just use our solution as if it were a [regular] petrochemical-produced plastic. This is a drop-in solution derived not from oil, but from plastic waste.”

There is already customer demand for this type of product, Peña Feliz said.

Brands have been hesitant to adopt recycled materials because the quality often has not been high enough, the cost was too high, and there were reliability issues with supply, he said.

“If you eliminate these three problems, the industry is ready to widely adopt these recycled plastics.”

Climate funding is at a crossroads

The company, which was founded in 2023, first raised US$500,000 from the Bill Gates climate fund of Breakthrough Energy. Two months after receiving this grant, it raised another US$500,000 in pre-seed funding.

That capital enabled the company to achieve enough milestones to secure a seed round in early 2021 of US$6.5 million in dilutive funding. MacroCycle has also raised nearly US$1 million in multiple smaller grants through companies and the state of Massachusetts, Peña Feliz said.

Peña Feliz and his co-founder plan to produce the product at larger scales to prove it’s a true “drop-in solution,” he said.

Once they achieve that milestone, MacroCycle will then raise another round of capital for a “significantly larger amount” to deliver product launches and “create impact at a larger scale,” Peña Feliz said.

For climate tech funding writ large, it’s definitely harder for entrepreneurs than ever before, Peña Feliz said.

“It’s undeniably harder to get money, the way the market has shifted,” Peña Feliz said. “More and more validation is required at earlier stages for companies,” and this can be a hard hurdle for many companies to clear.

“Investors still have capital to deploy, but their risk tolerance is lower,” he said. “Now companies need to demonstrate more and more to get the same load of capital.”

While raising money in the private sector and from venture capital firms is challenging, there are other difficulties when trying to raise money from public institutions.

“The bigger situation right now is geopolitical uncertainty, and this makes it more difficult to understand which grants to apply to, and to know if that capital will ever be deployed.”

Future plans

MacroCycle Technologies will eventually set up a site to pursue large-scale manufacturing, which will not be in the Boston area.

But MacroCycle’s founders will be staying put in Cambridge, MA for the time being.

“Right now we see a lot of benefit to staying in Massachusetts,” Peña Feliz said. “Cambridge is a hub of innovation, there are a lot of capital ventures nearby, and it’s the right place to grow our team and scale up.”

What’s next on the horizon, though, is the final Startup World Cup competition in October, to be held in San Francisco. MacroCycle will compete against other regional winners, for a grand prize of US$1 million in investment.