Insider Brief:

- Jaguar Land Rover has saved over £100 million from refurbishing, reusing and recycling equipment as part of a new decarbonization drive.

- The company has reused more than 50,000 square meters of manufacturing equipment and tools to help build its electric vehicles.

- A leader in this shift has shared the lessons JLR has learned in making reuse, refurbishing, and recycling a success.

Jaguar Land Rover is forging new ground, undertaking substantial shifts to encourage equipment reuse in its factories across Europe.

The company has embarked on a company-wide move, not only from internal combustion engines to electric cars, but also in reducing waste at every level of manufacturing and production.

JLR has saved over £100 million from refurbishing, reusing and recycling equipment, reusing more than 50,000 square meters of manufacturing equipment and tools to help build its electric vehicles.

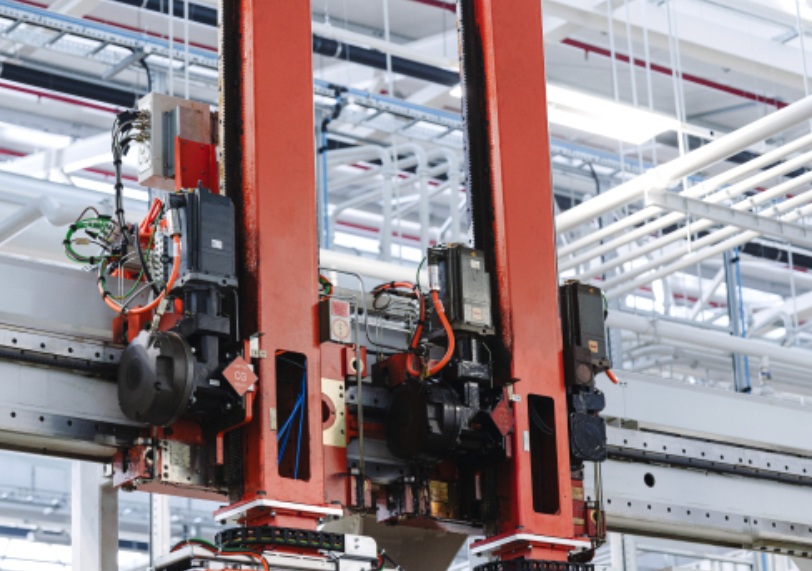

Equipment from its Castle Bromwich production plant, no longer in use, as well as the Electric Propulsion Manufacturing center in Wolverhampton, is now being redistributed throughout JLR plants to be used to build new cars.

The reuse is applied to various manufacturing equipment ranging from complete assembly lines and robots to hand tools and other minor components. Hundreds of refurbished robots are being installed in several production plants throughout the UK to build JLR’s EVs and battery packs.

Tomasz Jozwiak, Manufacturing Engineering Asset Manager in Castle Bromwich, has been at the center of this occasionally “turbulent” journey, and emphasizes how this new approach is being rolled out within the company.

“Sustainability is a core priority for the business,” he told Climate Insider. That was the catalyst for why the company is transforming its supply chains now.

The shift also came about partially due to trade shortages because of the Covid pandemic, Jozwiak said. “There were shortages in supplies of certain equipment.”

This inspired the company to use other equipment laying around and put it back into use. “That really helped us with our supply chain resilience, that we didn’t have to delay programs,” he said.

“The dedicated asset management team is relatively new,” Jozwiak said. Previously, it was usually a part-time job for someone on the team, he added.

Due to the change in JLR’s strategy to focus more on electric cars, there was suddenly a lot of surplus manufacturing equipment in the company’s production plants, he said.

“We had to ask: what do we have, can we reuse it, can someone else use it, or should we break it down and recycle it?”

Jozwiak describes himself and his team as the link between all the different technical teams to help connect surplus manufacturing equipment with projects that may be able to reuse it. Once all internal reuse opportunities were explored, the company considered sales or recycling options.

“We’ve had quite a few successes” in transferring manufacturing equipment from one particular plant and technology to another, he said. “We’ve reused body shop equipment in new EV traction battery assembly lines.”

Shift in priorities required company reorganization

The shift from ICE-powered cars to electric cars was clearly laid out by the company, and took several years of planning.

Managing asset reuse at scale was a bit different, Jozwiak said.

“We never had that amount of surplus assets to manage at this scale and in such a short period of time,” he said. “It was a little bit unprecedented. I’ve been here 14 years, and I never saw anything like that.”

JLR has now invested more than £1 million in digital systems to be used for asset management. This technology allows asset managers to have immediate access to all information on the part or robot, its history, how it’s been used, and which parts were replaced.

The company has developed the first phase of this new digital system, with initial rollout due later this year.

Real impact on emissions

JLR estimates that 18,600 tonnes of scrapped metal from Castle Bromwich and its Austrian plant in Graz have been sent to be recycled, each tonne enabling to save an estimated 1,258 kilograms of carbon dioxide equivalent downstream – the incremental amount that would have been emitted to produce virgin metal from ore instead.

“We’ve had 50 adhesive pumps that we reuse in body construction lines” Jozwiak said, preventing emissions of approximately 200 tonnes of CO2e.

Refurbished robots have also saved carbon emissions, Jozwiak said. “Producing each robot can generate about 8 tonnes of CO2e, according to our suppliers” he said. “We’ve reused more than 600 of them from Castle Bromwich plant.”

Lessons from reusing materials and equipment

The most important lesson Jozwiak would share with other companies when using reused or refurbished equipment? “Adjust your expectations.”

“When you’re dealing with used equipment, you cannot treat it like new. It takes time and effort to assess the asset, to go and ask for help in the refurbishment, and to manage the risks,” he said.

“You might need to modify it, and you’ll need to consider the extra steps you’ll need to take to comply with legislation and safety.”

For some equipment, re-use won’t be an option.

“Re-use may not always be the right answer,” he said.

“Think about some hydraulic or pneumatic equipment that more and more gets replaced with electric equivalents which are simply more efficient. Reusing some of that hydraulic or pneumatic equipment may simply result in a massive energy bill, and the compressed air costs a fortune. You’ll need to carefully assess what you should re-use, and draw the line if it’s simply not good for the business or the environment.”

Communication is key for projects of this size to be successful, Jozwiak said.

It requires a lot of forward planning and a willingness to listen, he said. “We need to be looking at least two to three years into our cycle plan,” he said. “So, say I have robots – will I need them in the next few years before any new legislation or a new generation [of robots] is created?”

It also takes a lot of communication to get other teams on board with re-use, he said.

Some people have concerns that reusing equipment could slow down the production line and cause breakdowns. The team involved in those reuse projects need to carefully consider those risks, and put in place an adequate refurbishment plan and other mitigation actions to address those concerns and manage any residual risks.

“You need to get the data in front of them,” he said. “Bring them along for the journey, understand their concerns, and don’t just impose it on them.”

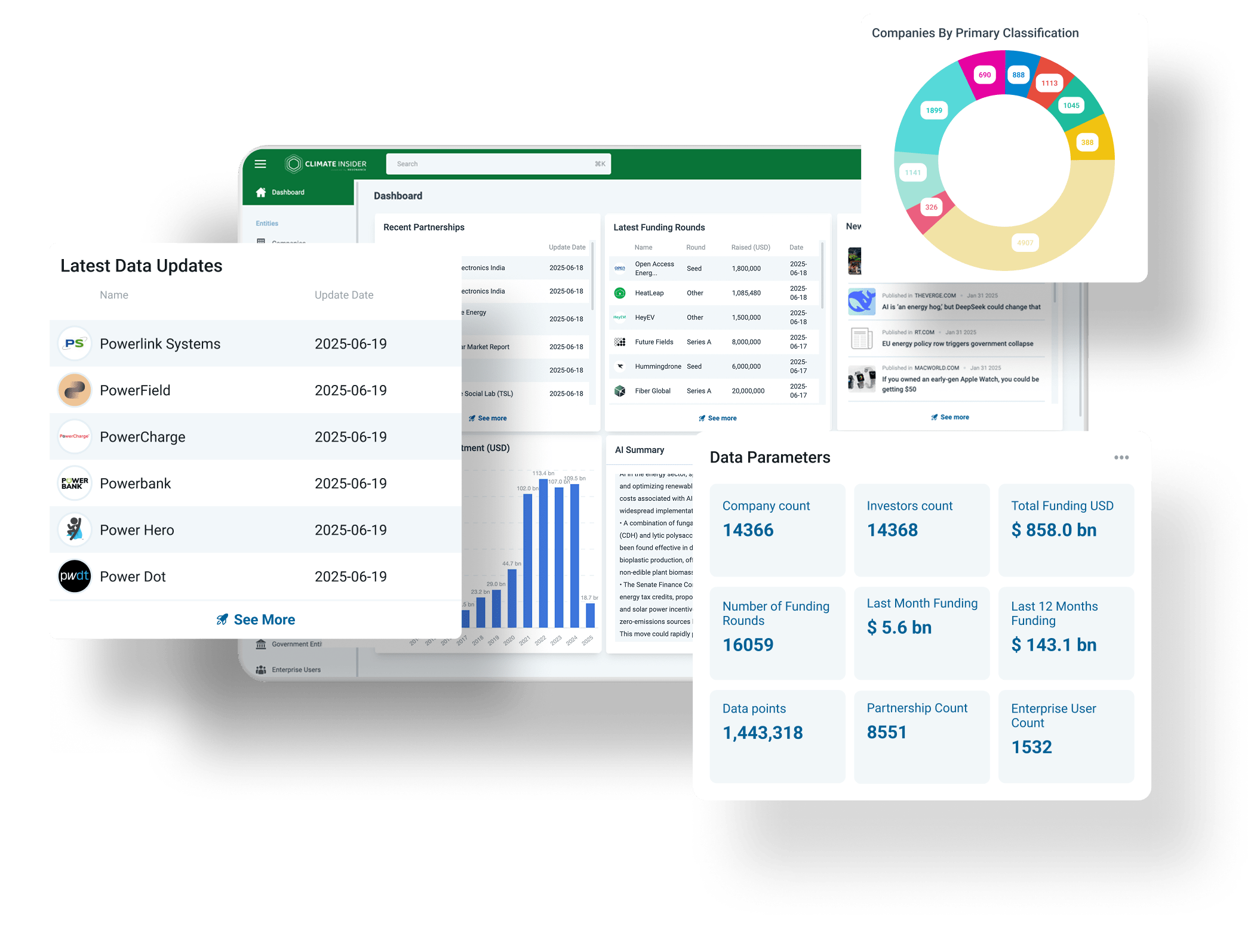

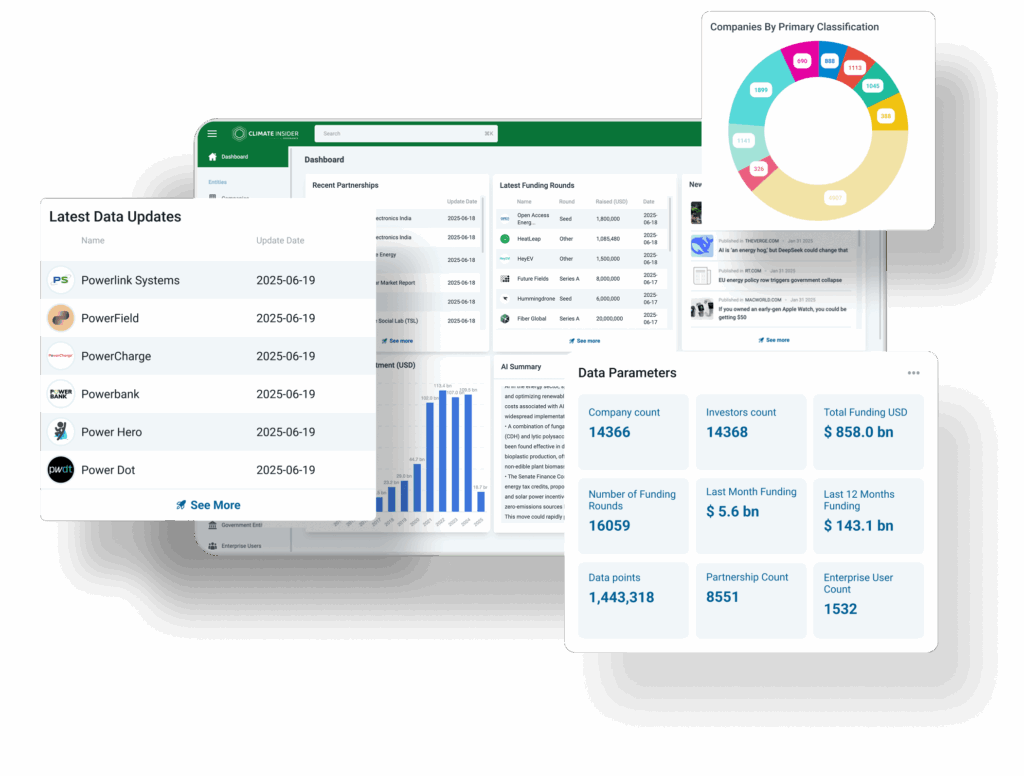

Climate Insider equips green economy businesses, industrial leaders, and policymakers with the clarity they need to navigate environmental demands and geopolitical pressures. Through our AI-powered market intelligence platform and expert-led advisory, users can identify commercially ready climate technologies, track policy and funding movements, and map critical ecosystem dynamics.

Ready to take the guesswork out of your climate strategy?

Get expert-backed answers at [email protected] or explore the platform at www.climateinsider.com to see how we help transform complexity into clarity.